- Home

- Solutions

- Solutions

- Engineering Solutions

- MT Installation System

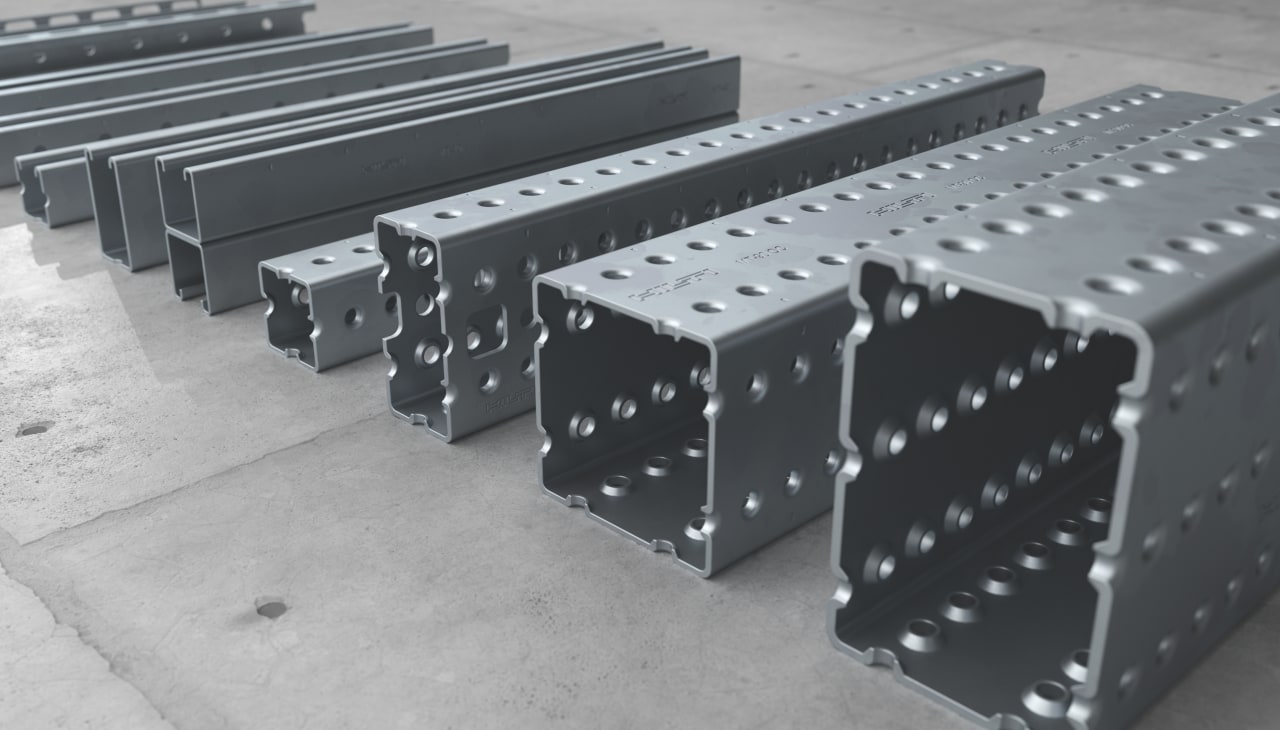

MT modular support system

A single seamless solution for your installation requirements

Easier to design and simpler to assemble, Hilti’s MT System is the only answer you’ll ever need for virtually all your installation support structures. Whether you are planning MEP installations such as pipe and cable tray supports, or access platforms and integrated floors for energy and industry projects, you’ll need just the one versatile, lightweight, and highly efficient system.

Do more with less

A cost-optimized solution for a wide range of modular support applications

With Hilti’s seamless MT System, we’ve got almost all your loading scenarios covered. This solution comes with corrosion resistance including zinc magnesium coating. It is ideal for light utilities such as air ducts and communication cables, as well as for cable trays and heavier cable ladders, and even for larger non-critical piping or heavier mechanical equipment. As a result, planning, managing and assembling your metal framing and support structures is easier than ever. In addition, by choosing the MT System, you can more seamlessly and simply combine all your MEP utilities in a single support structure that has been engineered for optimal efficiency.

Simplify planning

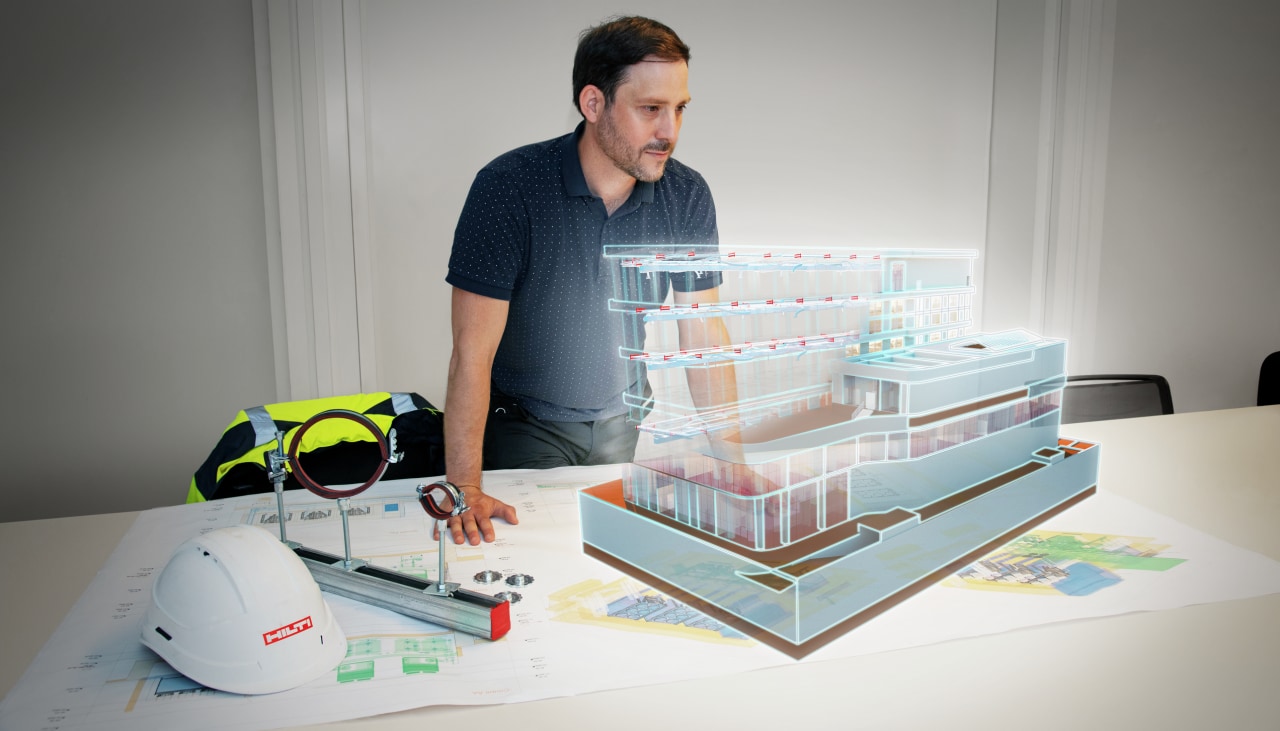

Easier integration of modular support design into your workflows

To help streamline design of your supports, Hilti has developed a powerful new range of dedicated software solutions. With PROFIS Modular Supports Engineering, you can create models of your supports, calculate them and export the final solution to 2D and 3D design platforms. Hilti also offers plug-ins for standard structural engineering tools (STAAD.Pro), and plant design modelling tools (Smart 3D). You’ll also have access to BIM/CAD library content and Revit families, thereby enabling the integration of the MT system design into your current workflows. Or use our Integrated Design Services to leverage industry-compliant building information modeling (BIM) methodology to increase productivity before, during and after construction.

Speed up assembly

Faster, safer and easier installation of modular support structures

Installation of MT girders, strut channels and other components is intuitive and seamless. Connect channels to girders with one hand thanks to thread forming bolts that eliminate the need for nuts and washers. To simplify installation, Hilti has also developed innovative Twist-Lock connectors that are inserted into the strut channel with a one-handed “push and twist” motion. When installed, they cut a groove into the channel allowing for rapid and highly accurate placement of components. The Twist-Locks do not slip before final torquing and can be repositioned later. What’s more, in some cases you won’t need connectors at all thanks to direct girder-on-girder or strut-on-girder connectivity. Even when utilizing the full range of MT components, you’ll enjoy a streamlined system designed to be as multipurpose as possible.

Prefabrication services

Boost efficiency with cutting, kitting and pre-assembly for modular supports

Hilti’s MT System can be cut and assembled on the jobsite with ease. It is completely flexible so that you can make adjustments in the field and save on costly rework — and of course it eliminates the need for welding. Alternatively, Hilti can support your project with cutting, kitting and pre-assembly services. Contact us today to find out more.

Fastening on steel solutions

Swap traditional welding for more productive and robust fastening of modular supports

Our cordless Stud Fusion welding solution for fastening modular supports to structural steel delivers the following benefits over traditional methods:

- Labor saving: certified welder is not required

- Speed: minimal preparation and no re-work on front or rear sides of base material

- Quality and consistency: robust fastening with real-time feedback from the tool

- Flexibility: without the drawbacks of traditional welding you have more freedom with engineering and planning and execution

- High-load fastening point: design resistance up to to 11.2 kN

Need assistance with fastening specifications? Access our library of calculations for pre-designed 'typical' support structure configurations, optimize your design with our PROFIS MSE software, or get full engineering support from our expert teams.

Cutting-edge corrosion resistance

Optimized indoor and outdoor solutions for modular support components

The MT System is designed to provide optimal corrosion resistance for both indoor and outdoor exposure. For indoor exposure, you’ll benefit from Hilti’s established high-quality solution where profiles are Sendzimir galvanized and connectors and baseplates are electro-galvanized. The outdoor solution combines hot-dip galvanized zinc (for components such as connectors and baseplates) and zinc magnesium (ZM) technology for profiles. ZM profiles conform to the ASTM A1046 and EN 10346 standards. With ZM technology, you’ll enjoy benefits such as more robustness and longevity, increased environmental friendliness and greater cost optimization. Since most of the steel in modular support structures is within the profiles, leveraging the benefits of ZM in this manner makes sense.

Leverage end-to-end digitization

Even if you're a seasoned BIM user, we can show you new ways to extend its benefits beyond the design team. Find out how high-tech construction equipment can save labor, time, administration and reduce the scope for errors.

Explore our integrated design servicesSolutions for raised floors

Speed up your installation and boost your operational flexibility with modular, all-in-one solutions for control rooms, server rooms and plant rooms that combine supports for floor tiles, cabinets and cable trays in one structure.

Explore raised floor solutionsYour partner for energy and industry

No matter where you are, get access to a global network of business developers and segment-specific solutions designed to to help bring down total costs over the life cycle of your assets.

Explore integrated energy and industry solutions