- Home

- Solutions

- Solutions

- Engineering Solutions

- Trade

- Fastening to Steel

- Fastening Electrical Equipment

MULTI-PURPOSE FASTENING

Fixing electrical boxes, cable ladders, cable trays, brackets and more

Steel base materials are usually pre-coated before they’re shipped to the jobsite, to protect against corrosion.

So, the challenge while fastening electrical boxes, brackets and other electrical instruments, is how to mount them to steel without damaging its protective coating.

To solve this, we’ve developed Hilti X-BT in stainless steel and Hilti S-BT studs, in duplex-coated carbon steel and stainless steel.

They’re compatible with Hilti’s modular support systems and are used in steel buildings worldwide, from skyscrapers to offshore platforms.

Use them to secure electrical panels, cable trays and ladders, electrical boxes, switch cables, cable tray supports and cable ladder supports.

SEE HOW OUR FASTENERS COMPARE TO WELDING, CLAMPING, BOLTING

Hilti X-BT direct fastening method

The Hilti X-BT stud is designed for a minimum base material thickness of ≥ 8 mm for highly corrosive environments (C5). Take a closer look at how they are used on the jobsite

The Hilti X-BT stud is designed for a minimum base material thickness of ≥ 8 mm for highly corrosive environments (C5). Take a closer look at how to install them

Hilti S-BT self-tapping fastening method

Use the Hilti S-BT stud in C3 mildly corrosive environments where the minimum base material thickness is ≥ 6 mm – and in highly corrosive environments (C5) where the minimum base material thickness is ≥ 7 mm. Take a closer look at how they are used on the jobsite

Use the Hilti S-BT stud in C3 mildly corrosive environments where the minimum base material thickness is ≥ 6 mm – and in highly corrosive environments (C5) where the minimum base material thickness is ≥ 7 mm. Take a closer look at how to install them

THE ADVANTAGES OF HILTI FASTENERS FOR STEEL

Our fasteners for steel are tried and tested

The Hilti X-BT has been used on some of the world’s toughest jobsites for more than 15 years. All our fastening technology is backed up by more than 75 years of Hilti engineering innovation.

Key features:

- Resistant to vibration

- Resistant to corrosion in C3 medium corrosive environments and C5 highly corrosive environments

- Works in a wide range of temperatures from -40 °C to +100 °C

- Comes with Type Approvals – so you can use them in projects worldwide

- Get help with your calculations – we provide recommended load values to help you work out how many fasteners you need. See more details in our Direct Fastening Technical (DFTM) Manual and the Hilti X-BT Threaded Fastener Specification

DOWNLOAD

-

DOWNLOAD OUR TECHNICAL MANUAL

Our fasteners are designed to not damage protective coatings – and to be quick to install

- Developed to speed up work on the jobsite, without the need for clamping, through bolting and welding - with no need for specialist trade skills such as welding

- No need for power cables – use with the Hilti SF BT-22A cordless drill

- Avoid rework – the Hilti X-BT and Hilti S-BT are designed to keep corrosion coatings intact on the steel base material during installation. They also come with an integral sealing washer, which protects against corrosion.

Fastening solutions for electrical applications

Highly corrosive environments (stainless steel-C5)

-

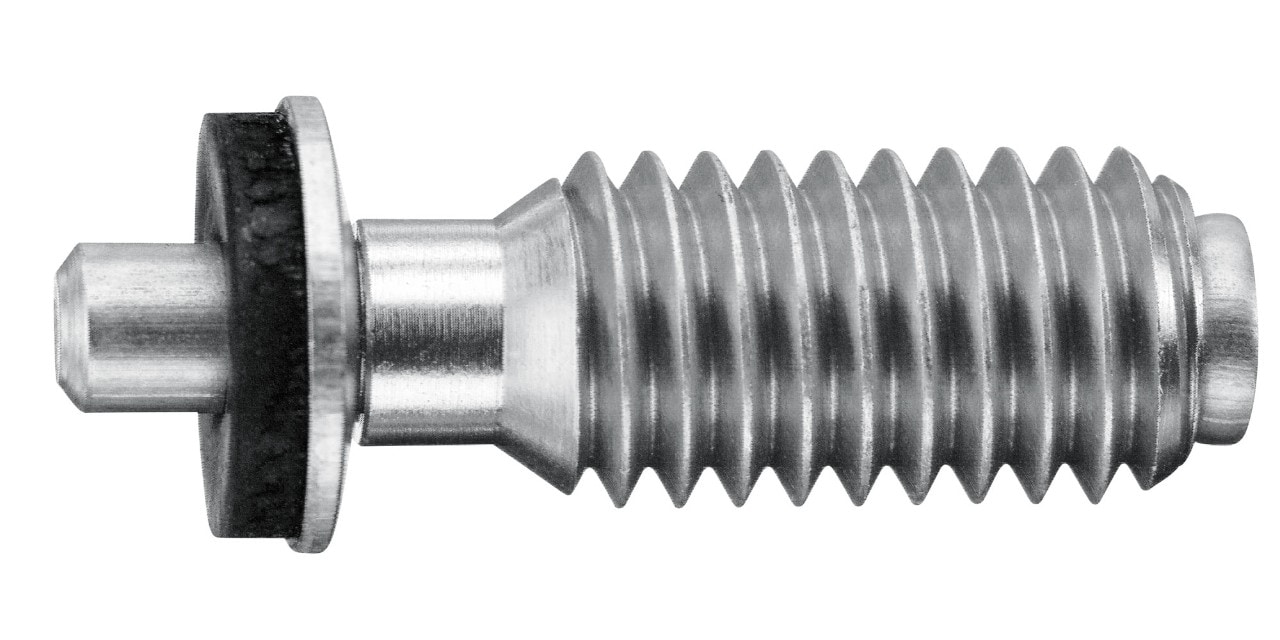

X-BT M10 threaded stud

X-BT M10 threaded stud

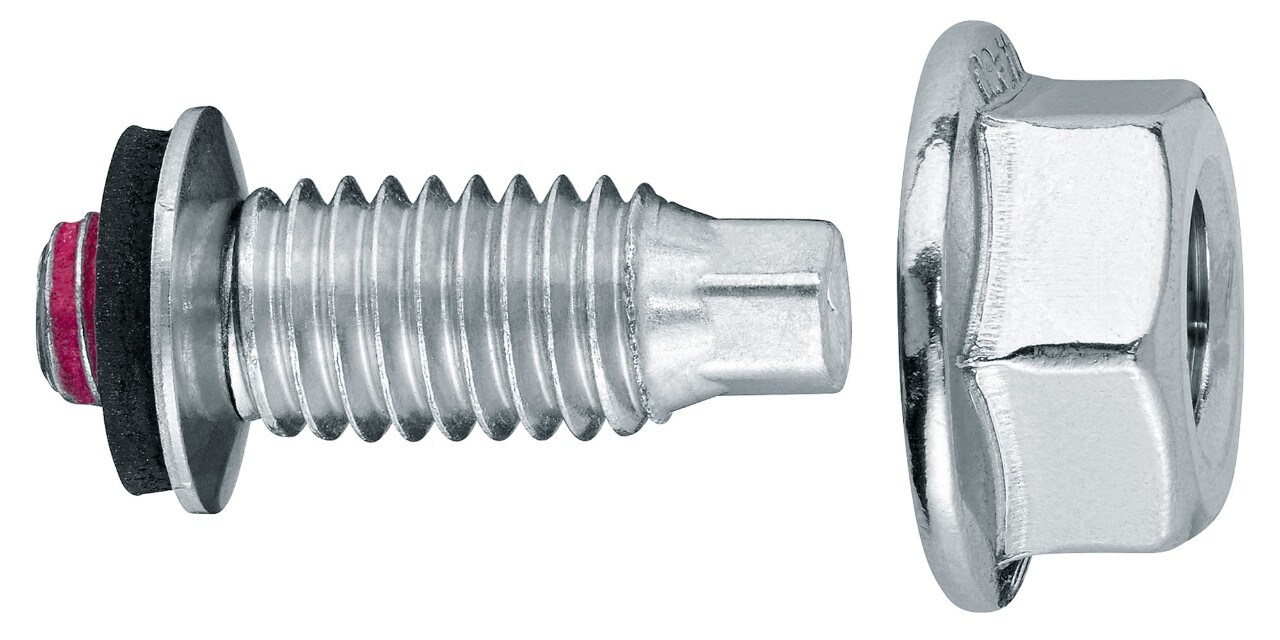

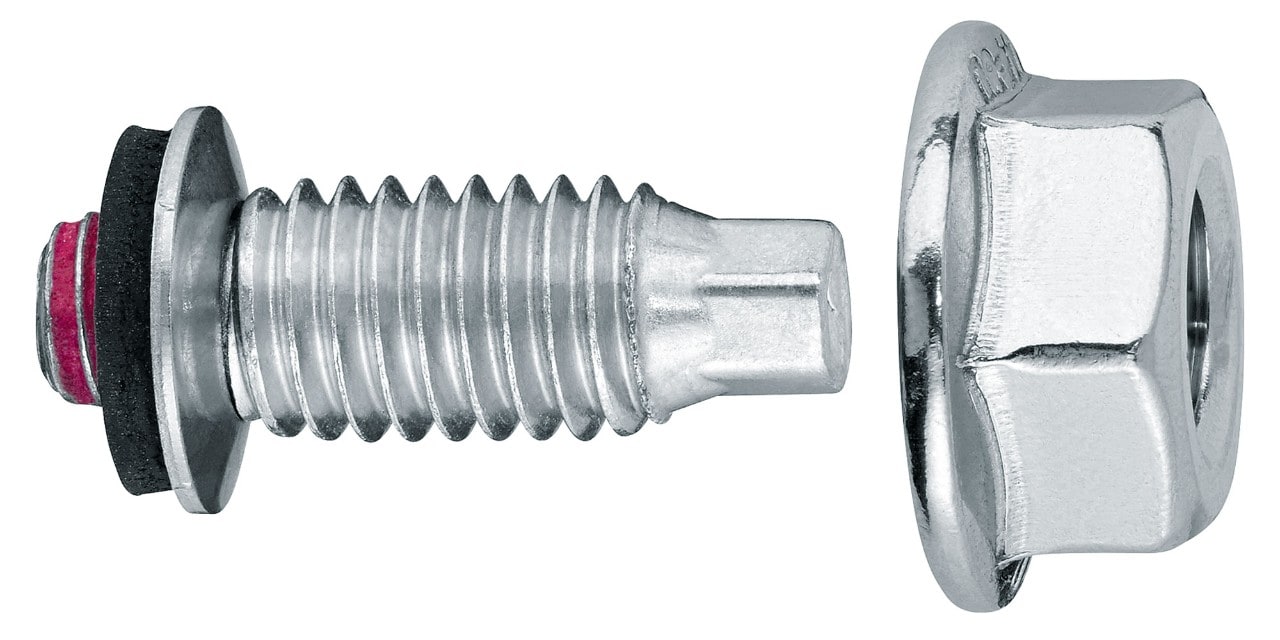

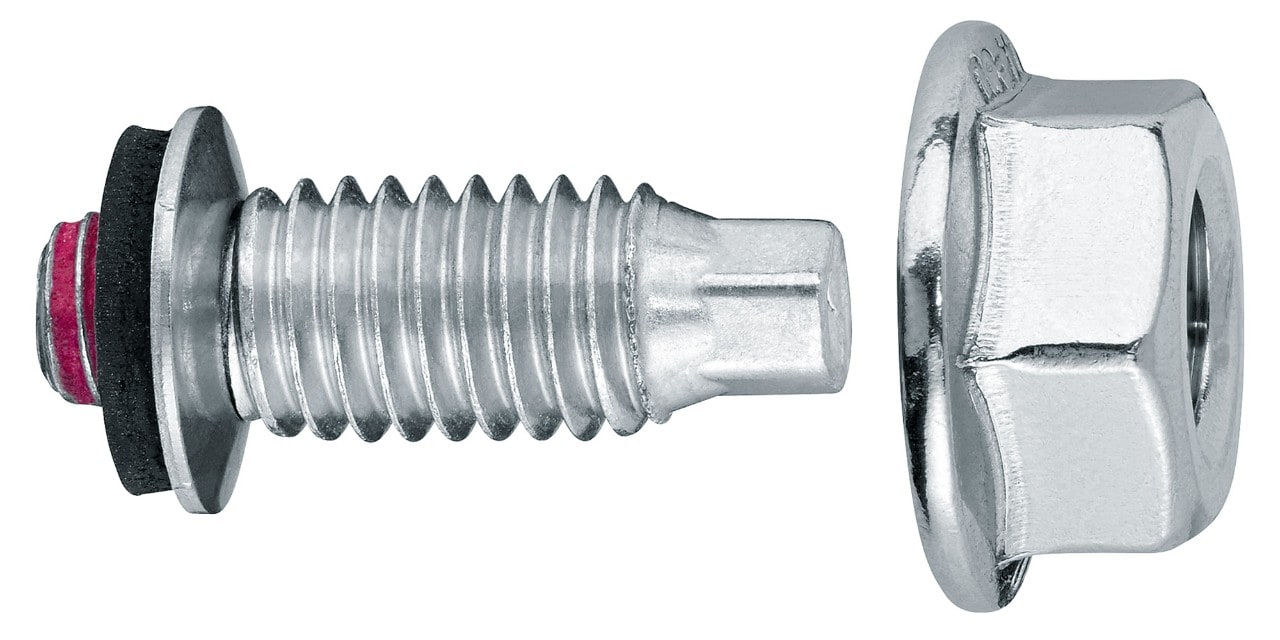

S-BT-MR M8 threaded stud

S-BT-MR M8 threaded stud

Mildly corrosive environments (hot-dip galvanized or slainless A2-C3)

-

S-BT-MF M10 threaded stud

S-BT-MF M10 threaded stud

X-BT-MF threaded stud

X-BT-MF threaded stud

S-BT-MF M8 threaded stud

S-BT-MF M8 threaded stud

PRODUCTS SPECIFIED FOR THIS SOLUTION

-

DX 351-BT fully automatic powder-actuated tool

More information

SF BT 22-A cordless drill

More information