- Home

- Solutions

- Solutions

- Engineering Solutions

- Road and Rail Tunnels

Road and rail tunnels

Transforming road and rail tunnel construction

Tunnels are demanding environments, requiring solutions that meet multiple requirements, such as dynamic loads and fire and corrosion resistance. Our portfolio helps make it simpler for you to design and specify approved solutions for different applications that comply with rapidly evolving global legislation. When you partner with us, you’ll benefit from dedicated software, products and services that can help bring enhanced productivity, quality, performance and safety to your tunnel construction projects.

ANCHOR DESIGN FOR TUNNELS

Quick, compliant design for complex applications

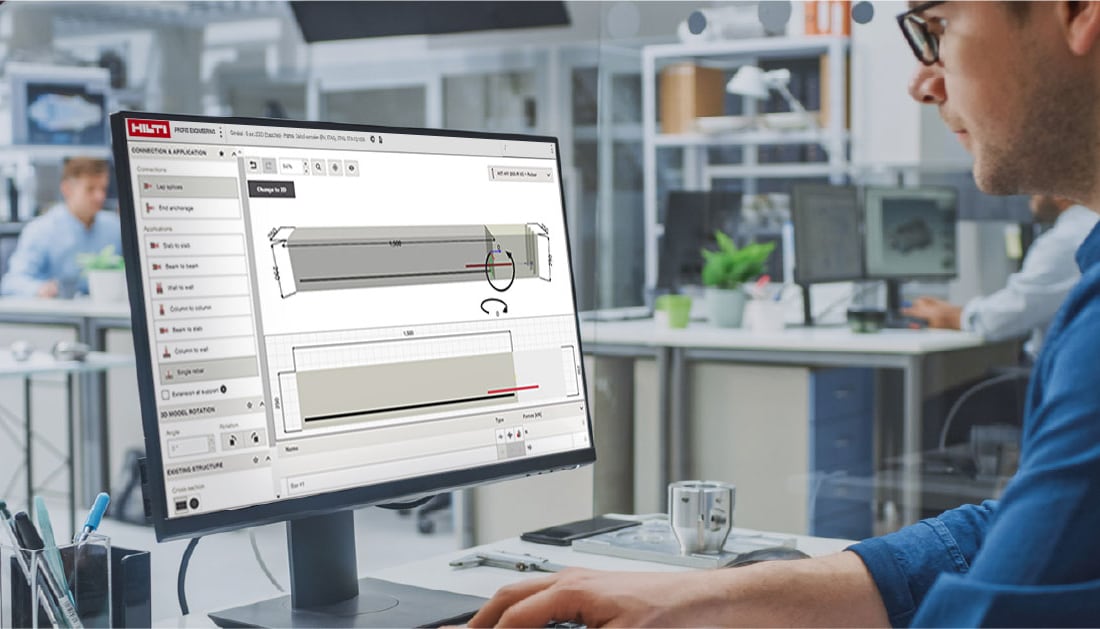

Anchoring applications are integral to all tunnel construction phases. Our cloud-based PROFIS Engineering Suite streamlines and speeds up the design of structural concrete-to-concrete and steel-to-concrete anchors, ensuring they automatically meet relevant codes and approvals. These include EN 1992-1 and Technical Report TR 069 for rebar design, EN 1992-4 for specifying baseplate anchors, plus European codes Technical Report TR 066 for the design of post-installed shear connections between two concrete layers. With PROFIS, anchor design becomes more accurate and faster, delivering compliant solutions for the most demanding environments.

BIM AND ADVANCED LAYOUT FOR TUNNELS

Transformational end-to-end workflows

Hilti BIM design services and digitized building tools are transforming tunnel design and construction. Powerful software allows everyone involved in design, construction and facilities management to participate in a highly efficient end-to-end workflow. 3D modelling capabilities allow you to integrate processes such as collision control and time/cost modelling, while solutions such as the laser fast PLT 300 digital layout tool makes implementing your design at the jobsite more accurate and efficient. Hilti also offers BIM support, helping you to integrate processes more effectively in your tunnel construction project.

POST-INSTALLED REBAR

Fire-resistant concrete-to-concrete connections for tunnels

When you need to create concrete-to-concrete connections in tunnels, Hilti chemical anchors offer a broad range of solutions for your applications. The SafeSet installation system eliminates steps such as hole cleaning, meaning post-installed rebar can be installed much faster. Fire-resistant mortars allow you to design applications that maintain structural performance under elevated temperatures.

Use PROFIS Engineering Suite to design rebar connections and benefit from fast-track calculations of performance and compliance. This accurate data helps you reduce potential conflict between engineers and installers. With no need to over-specify, what you design is what gets installed.

TUNNEL BASEPLATE CONNECTIONS

Durable fastening technology for fixing jet fans, walkways and more

Fastening requirements for steel baseplate applications in tunnel projects vary greatly. For example, jet fans are subject to dynamic loading while applications such as the fixing of walkways and handrails need to be durable, safe and compliant.

Hilti baseplate fastening solutions include options with a tested working life of 100 years, even when corrosion protection is required for challenging environments. The SafeSet system speeds up chemical anchor installation and makes connections more reliable, while Adaptive Torque system tools make anchor installation safer and quicker. Tracefast technology automatically documents each uniquely identifiable fastener, bringing exceptional quality assurance to your projects.

MODULAR CABLE AND PIPE SUPPORTS

High-performance fastening for challenging tunnel environments

Cables and pipes in tunnels require durable, high-performing and long-lasting fastening solutions. Depending on their location, whether behind wall cladding, under the roadway or above suspended ceilings, multiple performance requirements require different solutions. Hilti offers you a full portfolio of modular support solutions, including corrosion-resistant and seismic options, which can all be selected using our software. In addition, you can also benefit from engineering support services at every stage of your projects, from initial planning and BIM to detailed pre-fabrication, all with expert, on-site assistance.

CONTROLLED TUNNEL DEMOLITION

Faster, safer and more precise cutting with diamond wall and wire saws

When you need to undertake controlled demolition in tunnels, Hilti diamond tools make the process faster and more precise. They offer you a modern alternative to traditional heavy-cutting methods, which can not only be slow and expensive but can also risk damaging nearby structures.

Our diamond wall saws are easier to use and deliver faster cutting, even when working at height. Diamond wire saws let you cut to significant depths in reinforced concrete, both in wet and dry conditions. Browse our portfolio to discover tools that make controlled demolition safer and more accurate.

Take control of your inventory

What equipment do you have? Who’s using it and where? Do your tools need maintenance or calibration? Is it to time to renew training or certification? Get all this critical information and more in close to real time with ON!Track, Hilti’s equipment management software for the construction industry.

Find out moreDesign connections faster with PROFIS

Use PROFIS Engineering software to calculate and analyze multiple fixings, including steel to concrete, concrete to concrete, and steel to masonry as well as entire handrail and baseplate solutions that are more reliable, more cost-effective and code-compliant.

Find out moreHow Hilti engineers can help

Partner with Hilti to benefit from expert support through all stages of the project lifecycle from design to installation to building management. We offer everything from specialist advice and accredited training to on-site testing and engineering judgements to help ensure you find the approved solutions you need.

Contact us