- Home

- Solutions

- Solutions

- Engineering Solutions

- Fastening on Steel

- Electrical Connections

Fast, simple and reliable electrical connections

Steal back time when fastening on steel

Electrical connections are often needed on steel structures to provide a physical connection to earth for elements such as instrumentation panels, pipe flanges and other electrical equipment. By earthing (or grounding) the elements, you protect the equipment as well as reducing the risk of electrical shocks for people around them. This is particularly important in energy and industry settings, with outdoor environments such as power plants, oil refineries and offshore platforms.

Primarily these connections provide three important functions:

- Bonding

Simple act of joining two elements together – such as pipe flanges, cable trays or steel structures – so that at least one of them is then earthed so the electrical current can be discharged - Earthing (or grounding)

Connecting a part which does not normally carry current – such as equipment, junction boxes or storage vessels – to the earth - Lightning

Can be either direct (a lightning strike) or indirect (through power and communications lines or through the earth via the earthing system) and protection is based on catching the current and discharging it to earth (lightening conductors, catcher rods etc.)

Alternative methods for fastening on steel

Alternative methods can be time-consuming, labour intensive and require extensive rework to coated steel. For example:

Welding

- Time consuming preparation of the coated steel e.g. with an angle grinder

- Creates a lot of sparks, which can be a hazard

- An experienced and certified welder is required

- May require a hot work permit and, on some sites, a dedicated fire watch

- Multi-layer painting common in the Oil and Gas industry can take 3 to 6 days, including drying time, meaning expensive and time-consuming rework

Through-bolting

- Drilling process can be time-consuming depending on the thickness and hardness of the steel

- Steel exposed from the drilling must be properly coated to avoid corrosion

- Access to both sides is needed

- Installer needs to work with small parts such as nuts, washers and bolts that may get dropped or lost

Clamping

- Limited in direction of attachment of the component since clamps require a specific orientation relative to the structural steel

- Access to both sides of structural steel is needed

- Very high material costs, especially for corrosion-resistant clamps in hot-dip galvanized or stainless steel

Two fast and reliable ways for fastening electrical connections on steel

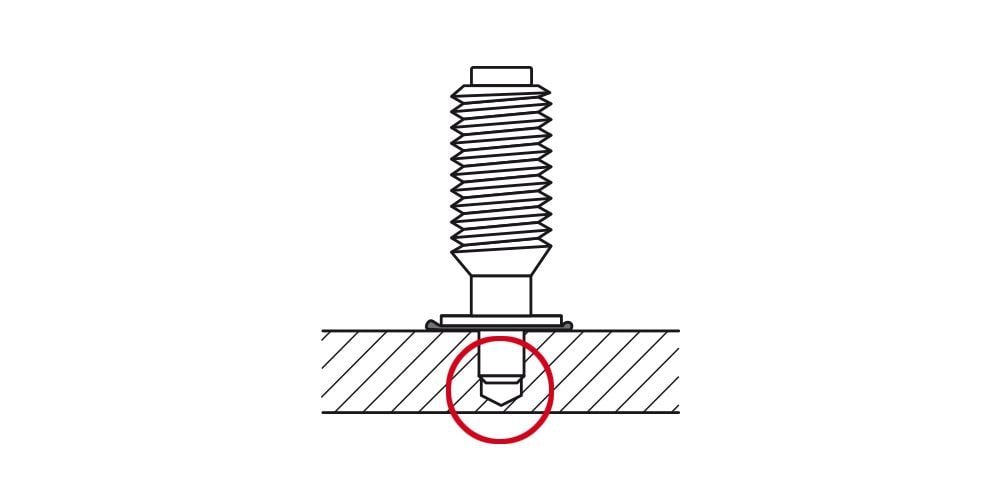

X-BT blunt tip fastening

A revolutionary fastening technology where a blunt-tip stainless steel fastener with a smooth cylindrical or conical shank is driven by a powder-actuated tool into a pre-drilled hole in the base material, creating a high-quality connection.

- No damage to the corrosion protection coating in non-through penetration applications

- Fastenings in less than 2 minutes

Duplex stainless steel fasteners for highly-corrosive environments.

Watch the blunt tip video

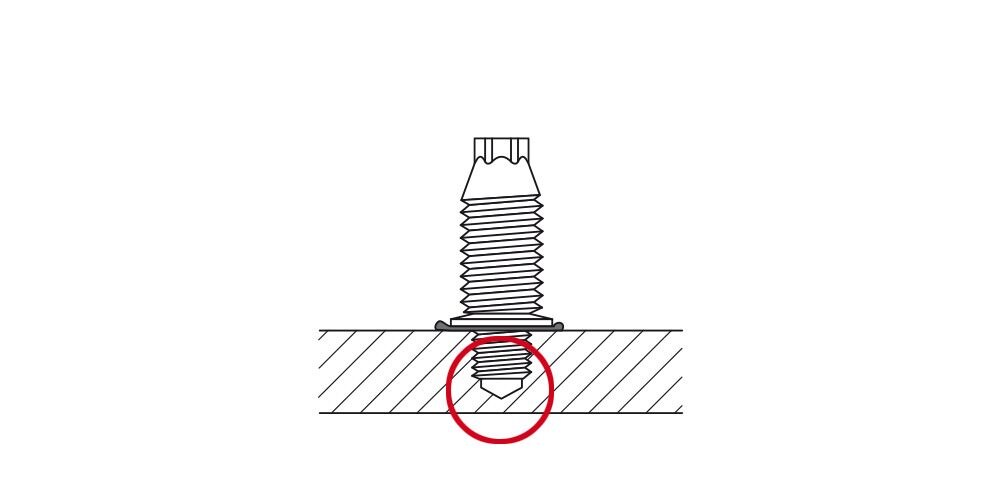

S-BT blunt tip screw fastening

A revolutionary fastening technology where a blunt-tip stainless steel fastener with a screw type shank is driven by a torque controlled screw driver into the pre-drilled hole in the base material creating a tapped connection.

- No damage to the corrosion protection coating in non-through penetration applications

- Fastenings in less than 2 minutes

Duplex stainless steel fasteners for highly-corrosive environments. Duplex coated carbon steel fasteners for mildly-corrosive environments.

Watch the blunt tip screw video (low current)Hilti fastening methods

Fast

- A connection can be made in less than 2 mins

- Recoating not required – no time-consuming rework!

- Significant total cost of install savings

Reliable

- Stainless steel stud suitable for highly-corrosive environments

- Vibration-resistant system prevents the connection from coming loose

- Wide range of approvals

Simple

- Simply drill, fasten and connect

- No external power source required

- Weather independent

Electrical connections portfolio

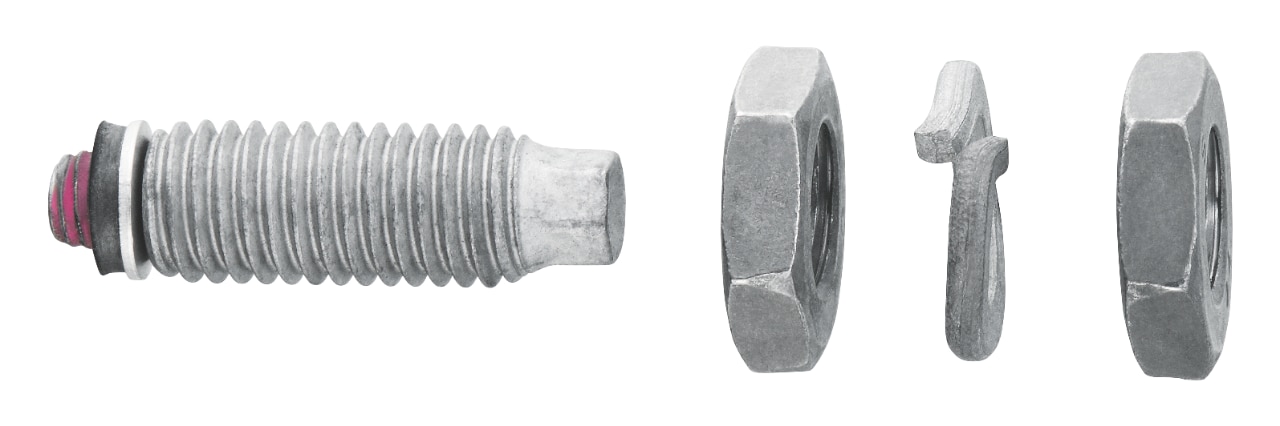

X-BT-ER threaded stud

Stainless steel for low current electrical connections on steel in highly corrosive environments

Maximum cable cross-section

Up to 10 mm² or 8 AWG

Current resistance (grounding)

Up to 1.25 kA for 1 sec (IEC)

Current resistance (lightning)

Class N 50 kA

Base material

Steel, stainless steel, cast iron

Minimum thickness

8 mm

Tool required

SF BT A22 and DX 351-BT(G)

Available thread diameter

M6, W6, M8, M10, W10

Fastener material

Stainless steel A4 equivalent

Product group

Low current

S-BT-EF threaded screw-in stud

Carbon steel (duplex coated) for low current electrical connections on steel, in mildly corrosive environments

Maximum cable cross-section

Up to 10 mm² or 8 AWG

Current resistance (grounding)

Up to 1.25 kA for 1 sec (IEC)

Current resistance (lightning)

Class N 50 kA

Base material

Steel

Minimum thickness

6 mm

Tool required

SBT 4-A22

Available thread diameter

M8, M10, W10

Fastener material

Duplex coated carbon steel

Product group

Low current

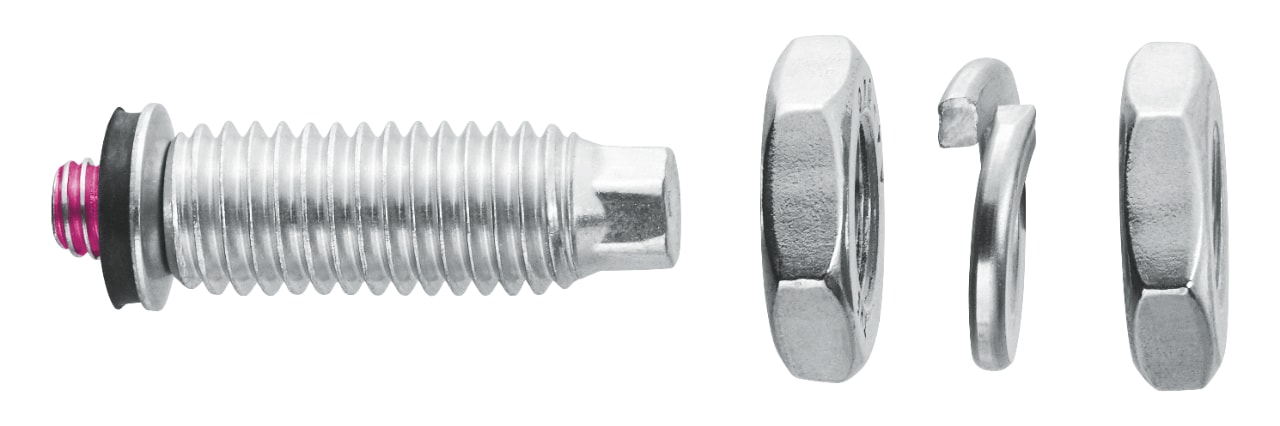

S-BT-ER threaded screw-in stud

Stainless steel for low current electrical connections on steel, in highly corrosive environments

Maximum cable cross-section

Up to 10 mm² or 8 AWG

Current resistance (grounding)

Up to 1.25 kA for 1 sec (IEC)

Current resistance (lightning)

Class N 50 kA

Base material

Steel

Minimum thickness

6 mm

Tool required

SBT 4-A22

Available thread diameter

M8, M10, W10

Fastener material

Stainless steel A4 equivalent

Product group

Low current

S-BT-EF HC threaded screw-in stud

Carbon steel (duplex coated) for high current electrical connections on steel, in mildly corrosive environments

Maximum cable cross-section

Up to 120 mm² or 4/0 AWG

Current resistance (grounding)

Up to 14.4 kA for 1 sec (IEC)

Current resistance (lightning)

Class H 100 kA

Base material

Steel

Minimum thickness

6 mm

Tool required

SBT 4-A22

Available thread diameter

M8, M10, W10

Fastener material

Duplex coated carbon steel

Product group

High current

S-BT-ER HC threaded screw-in stud

Stainless steel for high current electrical connections on steel, in highly corrosive environments

Maximum cable cross-section

Up to 120 mm² or 4/0 AWG

Current resistance (grounding)

Up to 14.4 kA for 1 sec (IEC)

Current resistance (lightning)

Class H 100 kA

Base material

Steel

Minimum thickness

6 mm

Tool required

SBT 4-A22

Available thread diameter

M8, M10, W10

Fastener material

Stainless steel A4 equivalent

Product group

High current